I asked my wife to help sift through all the research I did online and she came up with the following experiment to see which processes worked best for turning bone as black as possible without loosing too much of the surface texture. The results so far suggest that the rougher the bone’s surface the more the dye will infiltrate but it didn’t soak into the bone very deep on any of the pieces.

Bone Dying Test: Instructions

Degreasing (after this step, wear gloves)

- oven cleaner method: follow instructions on product

- dish soap: wash like a dish, rinse

- nothing: easy

Surface Treatment

- sand to 1500 grit

- sand to 1500 grit, then soak in vinegar 30 minutes and rinse in water with baking soda

- sand to coarse grit

Dyeing (use 2 small pots for different time lengths)

- put pieces into pot

- cover with just enough (normal temperature) water

- add a few drops dishwashing liquid

- bring to simmer (NOT BOILING)

- add ¼ bottle of dye (+ salt if dye container says so)

- keep at simmer (NOT BOILING) for either 15 minutes or 1 hour

- remove from heat and allow to cool (keep bone in pot)

- once water has cooled to room temperature, remove and rinse pieces

Finishing

try nothing, mineral oil, or carnuba wax

| 15 minutes in dye | |||

| no degreasing | dish soap | oven cleaner | |

| fine sand | 1 – light grey | 2 – light grey | 3 – light grey |

| coarse sand | 1 – grey | 2 – grey | 3 – grey |

| vinegar | 4 – near black | 5 – Black | 6 – Black |

| 60 minutes in dye | |||

| no degreasing | dish soap | oven cleaner | |

| fine sand | 7 – grey | 8 – grey | 9 – dark grey |

| coarse sand | 7 – black | 8 – near black | 9 – black |

| vinegar | 10 – Black | 11 – Black | 12 – Black |

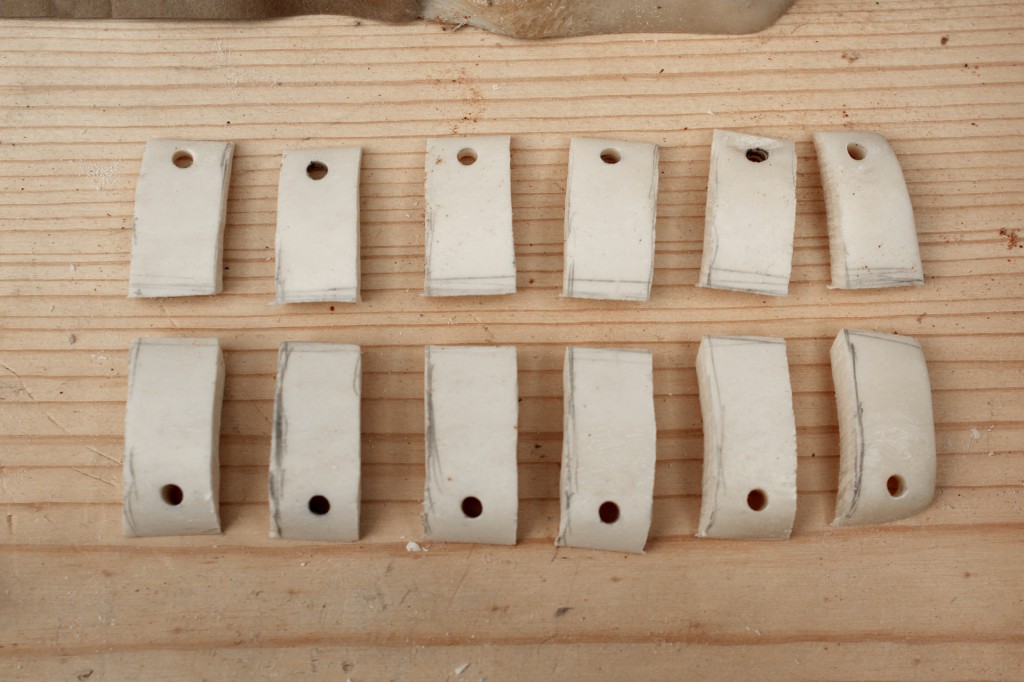

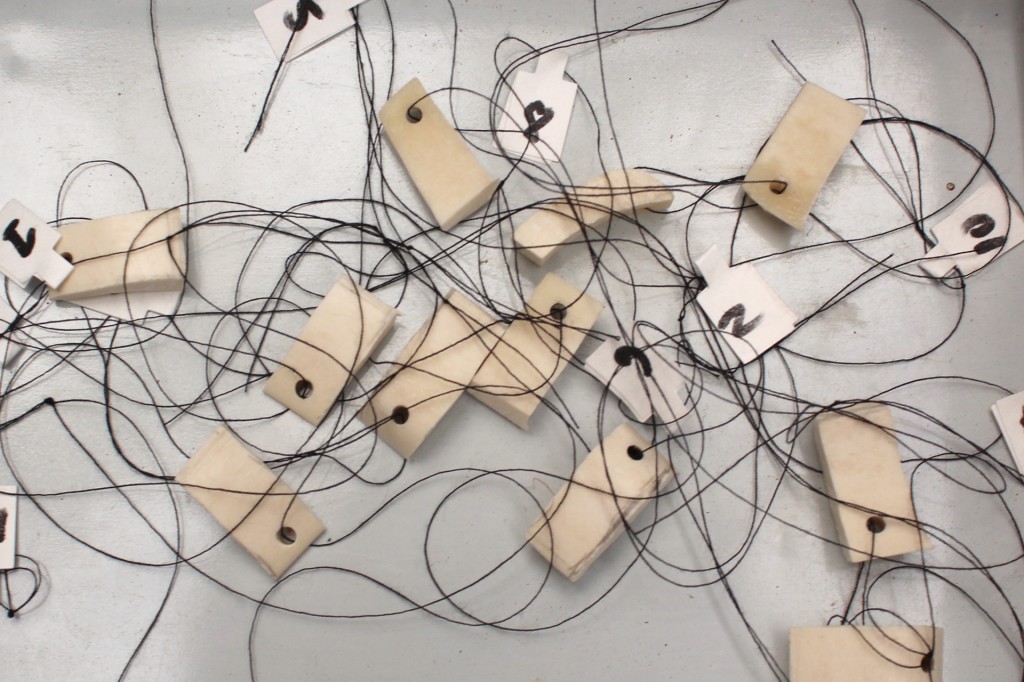

Photos of pieces after treatment:

Back to STUDIO TAPU HOME